Can a magnetic base with the switch fix equipment of different weights?

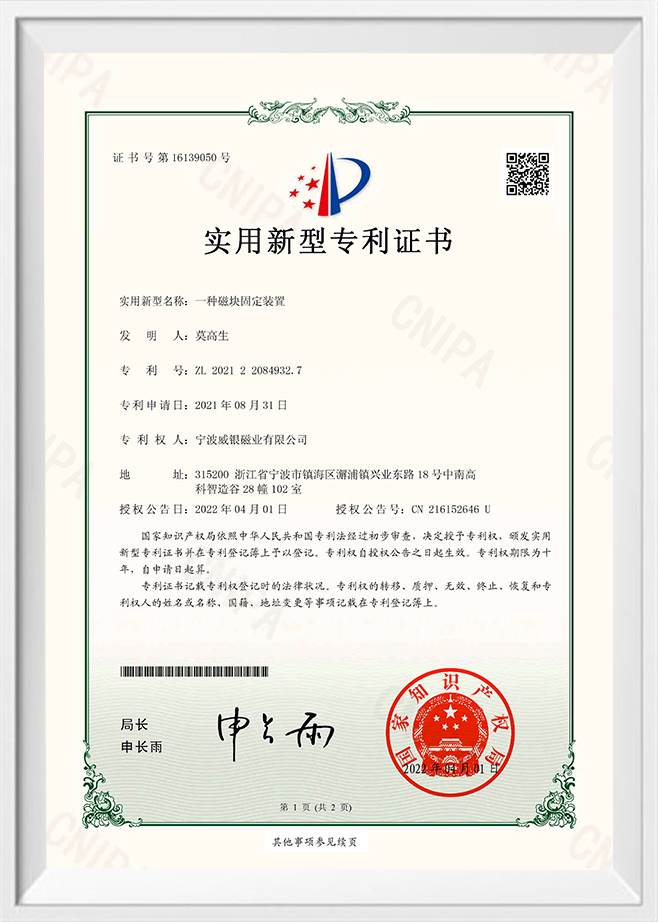

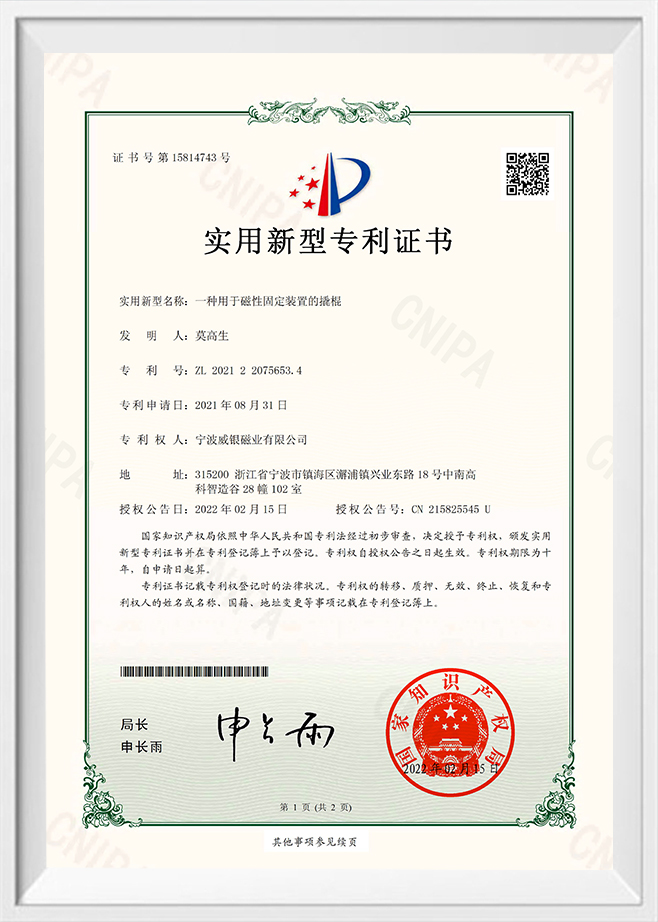

In industrial production, precision measurement, and daily maintenance, the issue of equipment fixation has always been the focus of attention. The magnetic base with the switch provides an efficient and convenient solution for the fixation of equipment with its unique magnetic adsorption and switch control functions. However, whether this magnetic base can fix equipment of different weights is an important issue that many users are concerned about.

1. Working principle of magnetic base

The core of the magnetic base with the switch lies in its strong magnetic adsorption ability. When the switch of the base is on, the internal magnet will generate a strong magnetic field, which can be firmly adsorbed on the metal surface. At the same time, the switch function on the base allows users to control the opening and closing of the magnetic field at any time as needed, so as to facilitate the installation and removal of equipment.

2. Adsorption force of magnetic base

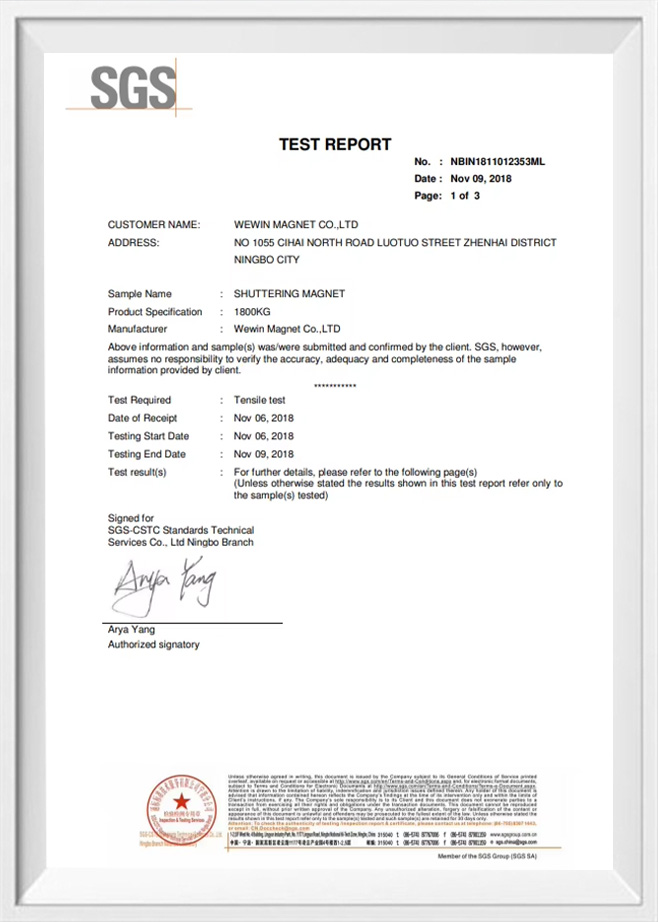

The adsorption force of the magnetic base is a key factor in measuring whether it can fix equipment of different weights. Generally speaking, the adsorption force of the magnetic base is related to factors such as its volume, magnet material, and magnetic field strength. The adsorption force of common magnetic bases on the market ranges from a few kilograms to hundreds of kilograms, which can meet the needs of different users.

3. The possibility of magnetic base fixing devices of different weights

Light equipment: For light equipment, such as small tools, sensors, etc., magnetic bases with switches can usually be easily fixed. Users only need to place the device on the base and turn on the switch of the base to quickly fix the device.

Medium equipment: For medium-sized equipment with heavy weight, such as measuring instruments, small machinery, etc., users need to choose a magnetic base with greater adsorption force. When fixing, users need to ensure that the equipment is evenly distributed on the base to avoid the base falling off due to uneven weight distribution.

Heavy equipment: For heavy equipment with heavy weight, such as large machinery, industrial equipment, etc., using a magnetic base alone may not meet the fixing requirements. At this time, users can consider using a combination of multiple magnetic bases, or combining other fixing methods (such as bolt fixing, welding, etc.) to achieve stable fixing of the equipment.

4. Precautions for use

Choose a suitable magnetic base: When choosing a magnetic base, users should comprehensively consider factors such as the weight, shape and size of the equipment and choose a base with sufficient adsorption force.

Pay attention to the cleanliness of the metal surface: Before using the magnetic base, users need to ensure that the metal surface is clean and dry to improve the adsorption force between the base and the metal surface.

Evenly distribute the weight: For devices with heavier weight, users need to ensure that the device is evenly distributed on the base to avoid the base falling off due to uneven weight distribution.

Regular inspection and maintenance: Users should regularly check whether the adsorption force and switch function of the magnetic base are normal. If there is any abnormality, they should be repaired or replaced in time.

The magnetic base with the switch can fix devices of different weights, but the appropriate base model and quantity need to be selected according to the actual situation of the device. During use, users need to pay attention to the cleanliness of the metal surface, the even distribution of weight, and the regular inspection and maintenance of the base to ensure the stable fixation of the device and the safety of use.