Key Benefits Of Shuttering Loaf Magnets

1. Easy installation and effortless operation. Your workers could choose a fixed position at will and quickly build concrete formwork according to individual architectural design. Significantly save complexity time and cost on the installation of magnetic formwork(up to 70%).

2. Universal use for mass production of concrete products, and piece different shapes and sizes of concrete elements of all forms on the same steel table. Excellent applicability, the same prefabricated formwork magnet can be adapted to different concrete formworks. You do not need to have a lot of different forms for different products. The same magnet can be used for different purposes and in different ways. You only need a set of magnets, adapters for boards of different heights, and a steel table. Your workers could contemporaneously build different concrete formworks at one time; even during the building process, your workers could adjust the concrete formwork.

3. Integrated threaded holes M12 and M16 to adapt formwork and customized adapters, to fix all kinds of side-formwork including wood, steel, and aluminum formworks, eliminates the need for welding, and shuttering magnets do not damage the steel table. Avoid welding or bolting to the formwork table therefore preserving surface finish and reducing direct damage to the concrete platform in the working.

4. No welding process is required, and the magnetic force of the magnet can be used to fit the template. Avoid welding or bolting to the formwork table therefore preserving the surface finish. No need electric welding, you can save high energy consumption.

5.10-Year-long service life and reusable. Low cost. Short payback period.

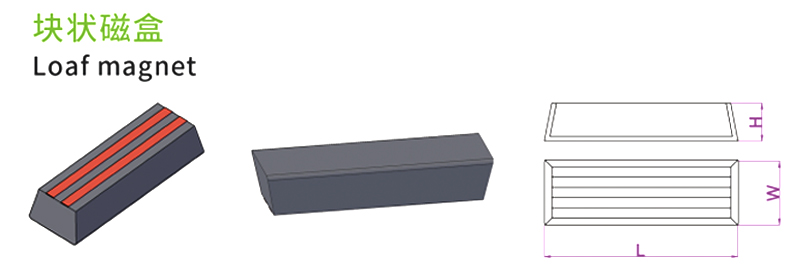

Specification of Loaf Magnet

| Model |

L(inch) |

W(mm) |

H(mm) |

Weight(kg) |

Pull Force(kg)

|

| WWSMA-G1 |

190 |

54 |

35 |

1.9 |

400 |

| WWSMA-G2 |

250 |

2.5 |

800 |

| WWSMA-G3 |

310 |

3.1 |

1200 |

| Other size on request |

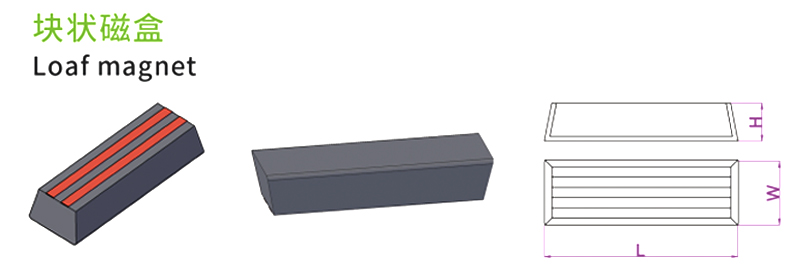

Structure and Elements of Shuttering Magnets

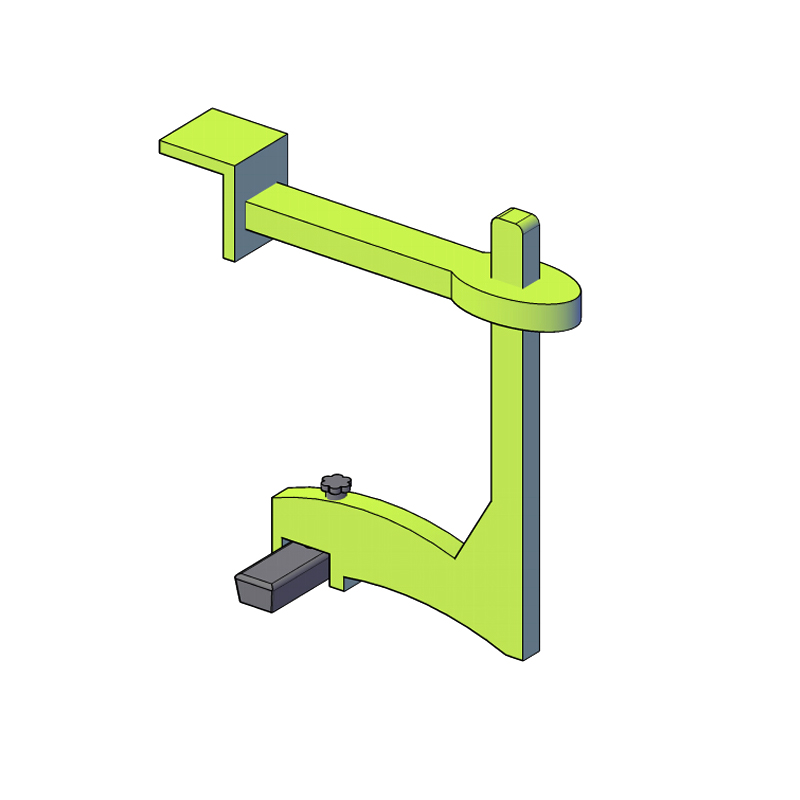

A loaf Magnet with a daptor accessory is applied for the production of precast modular components, with plywood or wooden shuttering forms. It’s designed with no button, compared to a standard switchable push/pull button magnet. It’s quite slim and occupies less of the steel table.

It simplifies the formwork mold installation, and the shuttering magnet needs to be located in the exact position by hand. Normally if there is a slight wrong position, you can use a rubber hammer to fix it. The next step is to install the adaptor accessory and adjust the tensile bar to fit your wooden mold height and make it support tightly. The bottom magnetic system could afford powerful resistance force against the forms moving under the circumstance of pouring concrete and steel platform vibrating, due to the integrated neodymium magnets. After work is done, a special release bar is provided to release it and remove it for further maintenance or next use. The stainless case features outstanding performance for anti-rust, which greatly increases the magnet's life.

Feature of Loaf Magnet

1. Adapter accessories: This bread magnet comes with an adapter accessory, which means it is compatible with different formwork or mold systems, increasing its versatility and applicability.

2. Button-less design: Unlike standard shuttering magnets, this magnet has no button design, making operation simpler and more direct.

3. Slim design: The design is very thin and provides strong magnetic force without taking up too much space, suitable for use in limited spaces.

4. Easy installation: The installation process is simple, just manually position the magnet to the correct position. If the position is deviated, a rubber hammer can be used for fine adjustment.

5. Adaptability: By installing the adapter accessory and adjusting the pull rod, it can adapt to wooden formworks of different heights to ensure that the formwork is tightly supported.

6. Strong support: Due to the integrated neodymium magnets, this magnet system can provide a strong fixing force for the formwork during concrete pouring and steel platform vibration.

7. Easy to release: After the work is completed, a special release lever can be used to release the magnet, which is convenient for removal maintenance, or reuse.

8. Durability: The stainless steel shell of the magnet provides good rust resistance, which helps to extend the service life of the product.

9. Precision Alignment: Provides accurate, stable positioning essential for precise alignment in formwork setups, reducing errors and improving setup efficiency.

Package of Loft Magnet

Our product packaging is suitable for air, sea, and land transportation. We will use magnetic isolation packaging for products with internal foam for fixation and external waterproof bags to prevent water leakage.