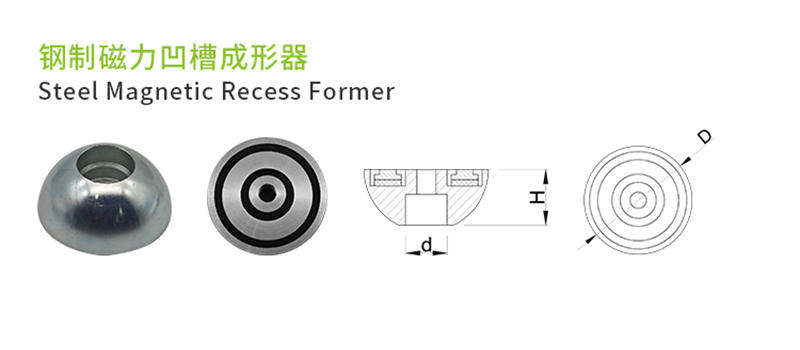

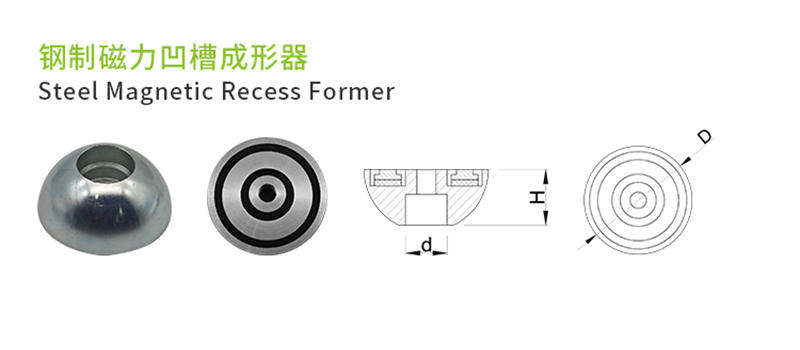

Overview of Steel Magnetic Recess Former

The Steel Magnetic Recess Former is a special-purpose magnetic device employed primarily for precast concrete applications. It provides for accurate fixing of lifting sockets positioning and fixing of cast elements, and efficient lifting and handling of the same. The magnetic power of the tool eliminates the use of adhesives or mechanical fasteners and simplifies the process, providing a firm grip on the mold surface.

The formers are available at various load capacities: 1.3T, 2.5T, 5T, and 10T which make them suitable for a wide range of applications. High-performance magnets, along with their robust steel construction, guarantee long-term reliability under demanding production conditions.

Specification of Steel Magnetic Recess Former

|

Model

|

D(mm)

|

d(mm)

|

H(mm)

|

Weight(kg)

|

Pull Force(kg)

|

|

WWRF1-1.3T

|

60

|

20

|

27

|

0.36

|

170

|

|

WWRF1-2.5T

|

74

|

30

|

33

|

0.66

|

260

|

|

WWRF1-5.0T

|

94

|

40

|

42

|

1.36

|

450

|

|

WWRF1-10.0T

|

118

|

50

|

53

|

2.68

|

650

|

|

Other sizes on request

|

Features of Steel Magnetic Recess Former

The Steel Magnetic Recess Formers engineered by Wewin Magnet Co., Ltd., assuredly feature the most advanced technology that surpasses the performance of other Steel Magnetic Recess Formers in numerous precast concrete applications. Here are the detailed features that make these tools indispensable:

1. Exceptional Magnetic Strength: The extremely powerful Steel Magnetic Recess Former is equipped with high-performance neodymium magnets. It will keep the device in place even when there is high vibration or pouring heavy concrete.

2. Precision Recess Formation: The designs of these units are perfect, giving the units uniform precision and perfect recesses for the socket or anchor lifting. This precision guarantees compatibility with standardized lifting devices and will reduce errors as well as save time for installation, lifting, and assembly.

3. High-Grade Steel Construction: Premium quality steel is used to manufacture these formers, which we know are built to last when exposed to arduous work in grueling industrial environments. The nice mechanical strength results from using steel in the body of the device, to allow it to bend and shape repeatedly without deforming or damaging itself.

4. Anti-Corrosive Treatment: All the steel surface is coated with advanced anti-corrosion coating in this process to prevent rust and other environmental damage. However, this feature increases the product’s life by prolonging its use in areas like outdoor precast production facilities in wet or humid conditions.

5. Ergonomic and Compact Design: Easy to handle and place the streamlined design. Its compact size makes it suitable when space is tight or for complex concrete designs that would be degraded in performance with larger units.

6. Heat and Wear Resistance: The Steel Magnetic Recess Formers are designed to be able to withstand high temperatures and abrasive materials, so they can withstand a tired environment from time to time. In particular, this feature is crucial for long production runs and continuous casting.

7. Enhanced Magnetic Isolation: To improve magnetic isolation, a special rubber layer is built into the design. This prevents direct contact between the magnet and the steel mold, preventing any chance of damaging the mold surface while doing so securely.

8. Reusable and Sustainable: The Steel Magnetic Recess Former is a reusable solution and thus, supports lowering operational costs and the environmental impact. It is a durable material, which means it can be used repeatedly without having an impact on performance and is, therefore, a cost as well as an environmentally friendly solution.

9. Shock Absorption Capability: These formers are integrated with a unique design that offers excellent shock absorption, making the formers stable under high pressure or high vibration conditions, such as large-scale concrete pouring.

10. Minimum Maintenance Requirement: Steel Magnetic Recess Formers have a strong structure and excellent wear and tear resistance, consuming little input and minimum maintenance, which makes them long and durable and easily ensures production with minimum downtime.

11. Customizable Options: Steel Magnetic Recess Formers can be customized to make them suitable for specific project needs on for specialized project.

12. Safety Enhancements: The strong and reliable magnetic force makes sure that the lifting anchor remains in its position during the casting and curing processes and removes any worries about the lifting anchor being dislodged. The possibility of this increase in safety during production and during precast element handling is increased.

Installation of Steel Magnetic Recess Former

Installing a Steel Magnetic Recess Former is a straightforward process that ensures maximum efficiency:

Preparation: The mold surface is cleaned to make sure the magnet stays in place. Remove any debris or grease which might spoil the magnetic connection.

Positioning: Put the Steel Magnetic Recess Former where it is needed on the steel mold. Make sure that it perfectly fits the lifting socket or anchor location requirements.

Secure the Anchor: The lifting socket or anchor is inserted into the recess former. The device will also be firmly held in position by the magnetic force used during the concrete pouring process.

Concrete Pouring: Then pour the concrete into the mold. The position of the recess former remains throughout the casting and curing stages.

Removal: Remove the Steel Magnetic Recess Former when cured, being careful. The recess you form will be nicely shaped and ready to use.

Importance of Steel Magnetic Recess Former in Precast Concrete

Steel Magnetic Recess Formers are critical to precision, steel, and safety in the modern production of precast concrete. Integration of these lifting anchors and sockets into industrial operations has become a game-changing solution for positioning and securing these important components, which up until now, presented considerable challenges. Below are the key reasons why Steel Magnetic Recess Formers are indispensable:

Improved Production Workflow: Steel Magnetic Recess Formers utilize the magnetic force to securely position lifting anchor or socket bases and thus eliminate the need for additional fastening tools, adhesives, or additional mechanical components. Not only does it ease your set but it also has a massive impact on speed of production time which means manufacturers can achieve a much faster project turnover.

Enhanced Safety Standards: Using Steel Magnetic Recess Formers directly increases the safety of manufacturing and handling practices for workers and structural components.

A cost-effective and sustainable solution.: Steel Magnetic Recess Formers are reusable and fray durable which makes them a good economical choice for a manufacturer. These magnetic tools, which unlike single-use adhesives or formers can be reused, reduce material waste and reduce overall operational cost over time.

Complex Production Needs Support: Steel Magnetic Recess Formers come in all sources and load capacities (1.3T to 10T) for just about all project inquiries from lightweight components to substantial precast concrete frameworks. By their adaptability, they can be used as a versatile tool for any manufacturer, since they are compatible with various design and engineering specifications.

Better Surface Quality and Mold Protection: The anti-scratch rubber layer built into the mold surface design helps to eliminate damage to the surface, but provides a firm grip while minimizing contact damage to the mold surface. It allows to protect the mold from falling and high-quality surface finishes on precast concrete products and extended mold life.

Efficiency in large-scale production: Consistent performance in high-volume manufacturing setups is provided by Steel Magnetic Recess Formers. Their capacity to carry on with repetitive operations with minimal upkeep prerequisites guarantees continuous processing cycles that in effect enhance operational effectiveness and profitability.

Alignment with Modern Construction standards: The recent increased demand for sustainable and efficient construction practices makes tools such as Steel Magnetic Recess Formers very important. They align with contemporary industry goals, and environmental regulations by reducing dependency on disposable materials and offer reusable, ecofriendly solutions.

Quality Assurance for load-bearing structures: With Steel Magnetic Recess Formers installed properly, load-bearing precast components are properly installed, passing safety and performance standards. For big projects, where structural integrity is less demanding, the reliability of such respects this crucial.

Why Choose Wewin Magnet Co., Ltd. for Steel Magnetic Recess Formers?

Wewin Magnet Co., Ltd. stands out as a trusted manufacturer of Steel Magnetic Recess Formers for several reasons:

Unmatched Quality: We are committed to quality control of our products so that they follow the highest industry standards.

Innovative Designs: Whilst we continue to innovate, we are constantly improving on efficiency and reliability to enable products in precast concrete production.

Extensive Product Range: We offer loads from 1.3T to 10T based on the project's needs.

Competitive Pricing: We provide you with high-quality Steel Magnetic Recess Formers at unbeatable prices.

Global Reach: We have years of experience with a robust distribution network so we serve all across the globe with timely delivery and magnificent customer service.

Custom Solutions: With our products tailored to client demand, this can guarantee complete customer satisfaction.

Wewin Magnet Co., Ltd. Steel Magnetic Recess Formers come in a variety of precast concrete projects. These tools combine precision, durability, and ease to use so that you can optimize your production process. Wewin Magnet Co., Ltd. guarantees you the best magnetic solutions that are easy to trust. To learn more about our Steel Magnetic Recess Formers and find out how they can help your business write us today.